WNiFe Tungsten heavy alloy plate in stock

- Model

- WNIFE-004

Item specifics

- Model Number

- WNiFe heavy alloy sheet

- Shape

- Sheet, Plate, Foil, Block

- Dimensions

- Customzied

- Density

- 18.5g/cm3 min

- Surface

- Hot rolling , cleaning , polished

- Brand Name

- GETWICK

- Application

- Ordnance,Mechanical

- Material

- Tungsten alloy, 97Wnife ,95Wnife, 90Wnife

- Chemical Composition

- W95%+Ni2%+Fe3%

- Cetification

- ISO9001:2015

Review

Description

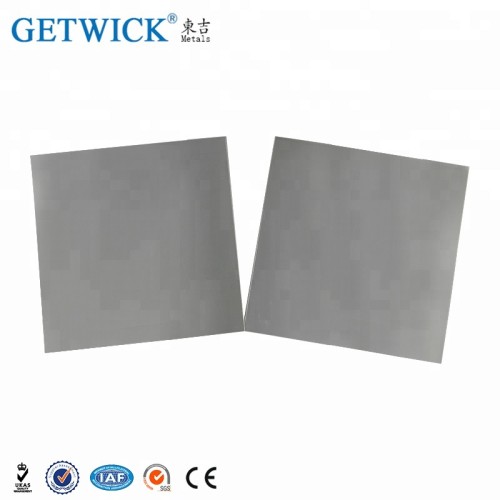

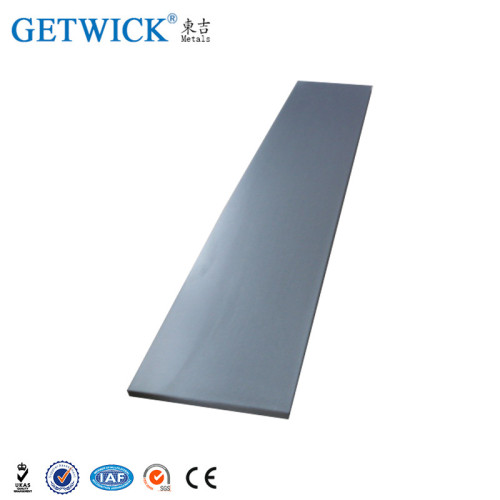

WNiFe Tungsten heavy alloy plate in stock

Description:

By adopting the tungsten heavy alloy manufacturing method, the plates from GETWICK possess excellent mechanical property. Tungsten heavy alloy plates can be widely applied in medical electronic, nuclear industry, chemical metallurgy and machinery processing industries.

The tungsten heavy alloy plates produced from our company comply with the standard of ASTM B777-99.

Production process:

The manufacture processes of high precision tungsten heavy alloy plates involve methods of powder metallurgy and thermoplastic processing. The producing processes are as follows:

1. Mix tungsten powder of average particle size from 2.8 to 3.2μm with nickel powder, iron powder, trace of cobalt powder and yttrium powder in appropriate proportion. Then press the composition in blender mixer.

2. Under the protection of hydrogen gas, raise the temperature at about 1500℃ in the rate of 15℃/min and preserve heat for two hours. Then we get the plate blank of tungsten heavy alloy plate ;

3. We adopt stainless steel plate as the package material of plate blank. Then press it under high temperature between 700℃ and 900℃.After several rounds of processes, when the total process rate reaches above 25%,we adopt vacuum heat treatment to eliminate stress for two hours under the conditions of vacuum 6×10-3pa and high temperature of 1000℃ to 1250℃;

4. Conduct another several rounds of pressing process under temperature between 700℃ and 900℃.When the total process rate reaches above 70%, we could get good semi-finished plate blank of tungsten heavy alloy plate.

5. Finally, we could get the end plate blank of tungsten heavy alloy plate after conducting annealing process and last round of pressing under the high temperature of 1000℃ to 1100℃.

Applications:

1.Tungsten heavy alloy plates can be widely used as balancing weights and high temperature moulds;

2.They can also be used as protection shields for high-energy rays;

3.Tungsten heavy alloy plates also can be used for producing aircraft control surfaces, helicopter rotor systems, engine components, ship ballasts, golf club weights, boring bars and down hole logging-sinker bars, etc;

4.They can be produced as the materials for making fire arms and ordnance.

Features:

1.Tungsten heavy alloy plates have a very high density between 16.8g/cm3 to 18.75g/cm3, which is twice as much as that of steel and more than 50% heavier than lead;

2.They are of low thermal expansion coefficient, high strength and high modulus of elasticity;

3.They have high absorption capacity of high-energy rays.

Parameters of Tungsten Heavy Alloy Plates:

Class | Nominal W | Density | Max. hardness | Tensile strength | Elongation |

weight% | g/cc | Rockwell ‘C’ | MPa | % | |

Class1 | 90 | 16.85-17.25 | 32 | 700-1200(600-800) | 20-33(4-8) |

Class2 | 92.5 | 17.15-17.85 | 33 | 700-1400(500-600) | 15-25(3-5) |

Class3 | 95 | 17.75-18.35 | 34 | 700-1200 | 8-15 |

Class4 | 97 | 18.25-18.85 | 35 | 600-1000 | 8-14 |

Note: The data in brackets apply to non-magnetic nickel-copper tungsten heavy alloy plates. | |||||