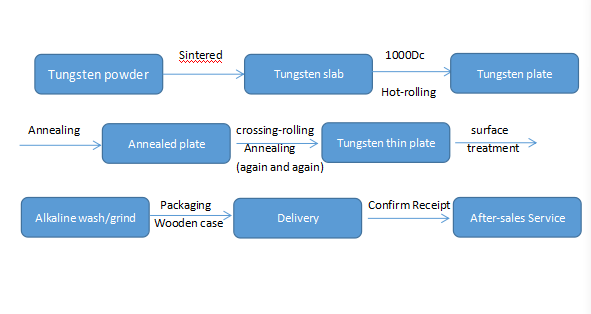

Tungsten sheet for rolling tungsten foil and punching tungsten discs

- Model

- W1

Item specifics

- Material

- Tungsten

- Purity

- 99.95% min.

- Standard

- ASTM B760

- Grade

- W1

- Shape

- tungsten sheet, tungsten plate

- Working temperature

- 2000~2600Dc

- MOQ

- 1kg

- Surface

- black, chemical cleaning, polished

- Feature

- high temperature resistance

- Products Name

- 2019 hot sale putr tungsten plate from China

Review

Description

Item: tungsten plate and sheet

Materials: W1

Purity: 99.95%Min

Density: 19.35g/cm³

Melting Point: 3410℃

Surface: shiny, alkaline washed, satin, or as-rolled condition; dependent upon

thickness and width parameters.

Properties:

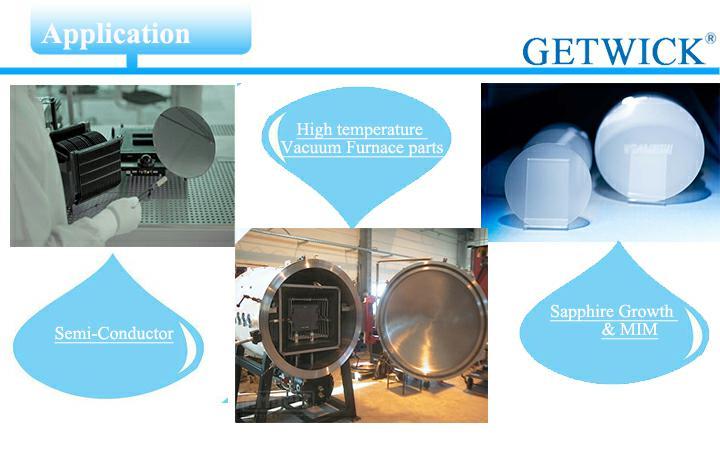

High Temperature Resistance

High Hardness

High Density

Feature:

Tungsten is the highest melting point of all metals.

Low coefficient of thermal expansion.

Very high level of dimensional stability.

Main Comp.W≥99.95 | ||||||

Other Content≤ | Fe | 0.0026 | Al | 0.0006 | Si | 0.001 |

| Ca | 0.001 | Ni | 0.0009 | O | 0.0018 |

| Cu | 0.0005 | N | 0.0015 | Pb | 0.0001 |

| Sn | 0.0001 | Sb | 0.001 | As | 0.001 |

| Cd | 0.0001 | Mg | 0.0006 | C | 0.002 |

| Bi | 0.0001 | Mo | 0.003 |

| |

Normal specification we can provide:

Tungsten Plate/Sheet /Foil | ||

Thickness(min) mm | Width(max) mm | Length(max) mm |

0.05 | 150 | 500 |

0.06~0.09 | 250 | 500 |

0.1 | 300 | 500 |

0.12 | 320 | 550 |

0.15 | 350 | 1000 |

0.2~0.6 | 400 | 1000 |

0.7~0.9 | 400 | 1000 |

1~2 | 450 | 1000 |

2~10 | 450 | 600 |

10~15 | 450 | 500 |

15~25 | 300 | 500 |

Tolerance Chart(mm) | |||||

Thickness | Width | Length | |||

Range | Tolerance | Range | Tolerance | Range | Tolerance |

0.05~0.2 | +/-0.01 | 30~200 | +/-1 | 50~400 | +/-2 |

0.2~0.3 | +/-0.02 | 50~300 | +/-1 | 50~400 | +/-2 |

0.3~0.6 | +/-0.03 | 50~300 | +/-2 | 50~600 | +/-2 |

0.6~1.0 | +/-0.04 | 50~300 | +/-2 | 50~1000 | +/-3 |

1.0~2.0 | +/-0.05 | 50~300 | +/-2 | 50~1000 | +/-3 |

2.0~4.0 | +/-0.1 | 50~300 | +/-2 | 50~1000 | +/-3 |

4.0~6.0 | +/-0.3 | 50~300 | +/-2 | 50~600 | +/-3 |

6.0~ | +/-0.5 | 50~300 | +/-3 | 50~600 | +/-3 |