High Purity Tungsten Crucible for Melting

- Model

- W1

Item specifics

- Density

- 19.35g/cm3

- Purity

- 99.95%

- Size

- Customed

- Surface

- polished

- Working tempersture

- 2000-2600℃

- Melting poit

- 3260℃

- Application 1

- smelting of rare-earth

- Application 2

- quartz glass,

- Application 3

- electronic spraying

- Application 4

- crystal growth

Review

Description

High Purity Tungsten Crucible for Melting

We mainly produce,develop and sell Tungsten and Molybdenum plates ,sheets,foils,strips and boats,crucibles,vacuum furances and their subassemblies,sputtering targets,deep processing products ect, and Tantalum,Niobium,Titanium,Nickel,Zirconium,Chromium ect.other rare metals.The products are widely used in rare-earth,vacuum furance,glass fiber,industrial ceramic,chemical petroleum,aerospace ect,industries.

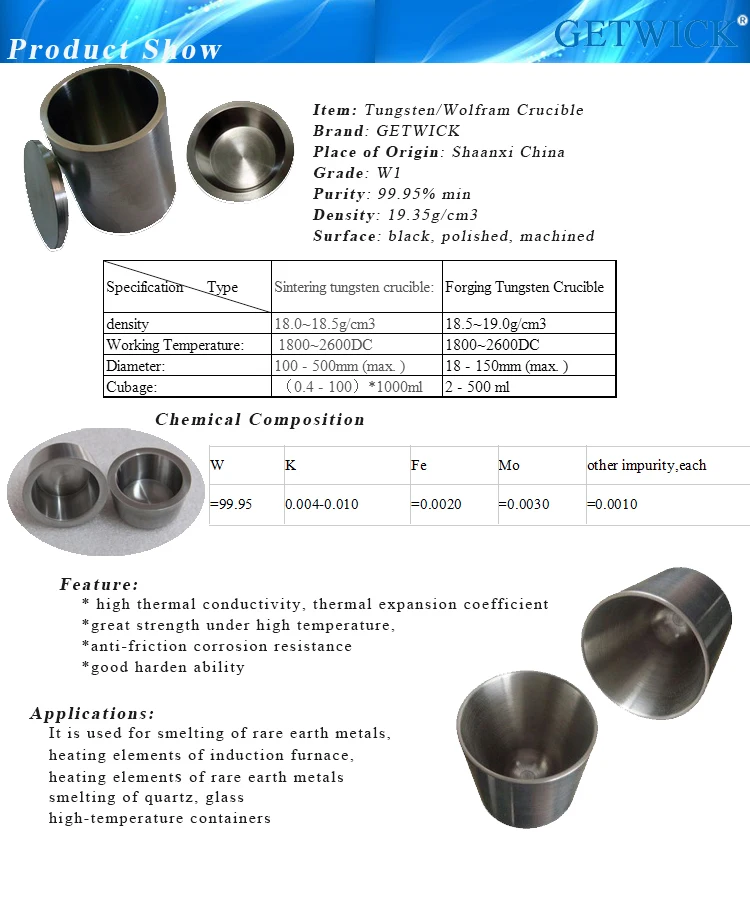

1.Application of tungsten crucible:

Tungsten crucible is widely used in sapphire single crystal

growth furnace, quartz glass melting furnace, rare earth smelting furnace and other core containers of industrial furnace. Its operating temperature environment is more than 2000 degrees.

Item Name |

GETWICK Tungsten Crucible |

Material |

Pure Tungsten and Alloy Tungsten |

Grade |

W1,W2,WAL1 |

Specification |

as your order |

Applications | widely applied in industry furnace such as sapphire growth furnace, quartz glass melting furnace, and rare earth smelting furnace widely applied in industry furnace such as sapphire growth furnace, quartz glass melting furnace, and rare earth smelting furnace |

1. Condition: sintering or forging

Material | Density | Size |

w 99.95% | 19.1g/cm3(Forging) | Diameter:10-100mm; High:10-120mm |

w 99.95% | 18.3g/cm3(Sintering) | Diameter:100-650mm; High:50-850mm |

2. Measurements and tolerances(mm)

Delivery condition | Specification | Thickness | Roughness(μm) | |

Diameter | Height | |||

Sinter | 10~700 | 10~1000 | 5~30 |

|

Finished sinter | 10~650 | 10~850 | 7~25 | <2.5 |

3. Manufacturing process and equipment

Item | Process | Equipment | Quality Check point |

1 | Tungsten powder |

| 1.Purity of tungsten powder |

2 | Sieving | High frequency vibrating screen | 2.Fsss,HB |

3 | Mixed powder | V shape mixer | 3.Green strength |

4 | Isostatic pressing | Isostatic pressing machine | 1.Measurement of rough-processed billet |

5 | Rough billet lathing | CNC vertical turning machine | 2.Surface quality of rough-processed billet |

6 | IF sintering | IF induction sintering furnace | 1.Outside measurements of finished product |

7 | Competitive products lathing | High-accuracy vertical turning machine | 2.Surface quality and roughness of finishe |

Package

1.Carton with water proof paper and protective foam inside.

2. Standard export case.

3. As consumers' requirements.

Payment

1. Sample order: L/C, Paypal, Escrow and T/T100% are accepted.

2. Big order: T/T 50%, full payment advanced, L/C are accepted.

Please choose which terms is convenient for you. Depends on your order, we also will recommend the most suitable way.

Welcome to visite our company and make cooperation~~

Choose Getwick,Choose quality

Choose Getwick,Choose Service

Choose Getwick,Choose Speed

If you have any questions or confuse, please feel free to contact with me.