Boats are used for the vacuum evaporation of materials

- Share

- Issue Time

- Apr 3,2019

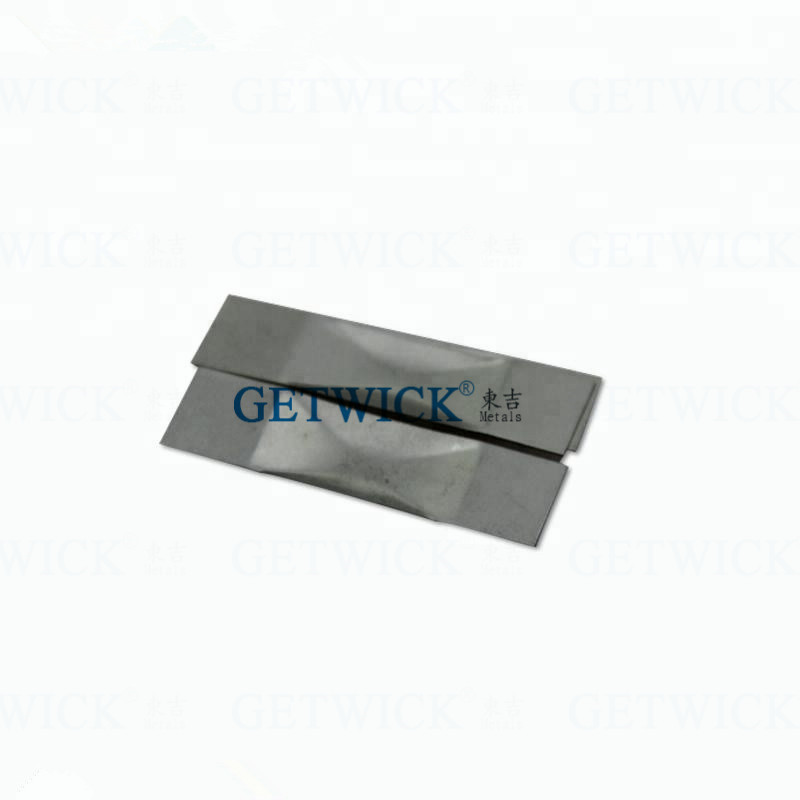

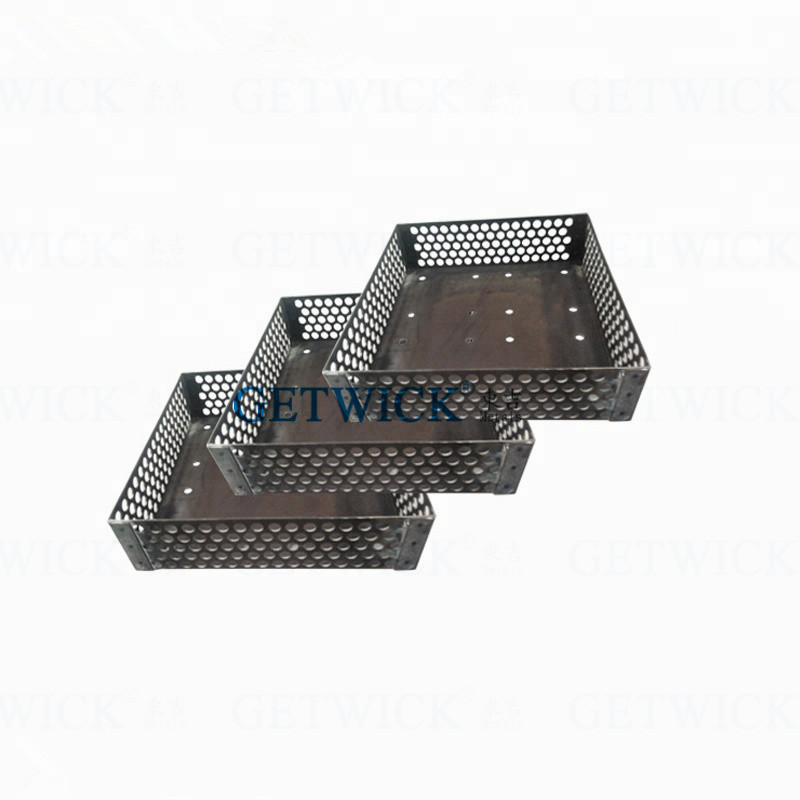

As a business unit we are the topmost manufacturer and supplier in the industry offering an impeccable range of Molybdenum Boat. It is designed after processing molybdenum plates with cutting, folding, riveting and welding. The boat shapes can be molded to meet the variegated requirements of the clients including round, rectangular, square and trapezoidal. The offered Molybdenum Boat is used in the vacuum thermal evaporation air, capacitor sinter, nuclear fuel sinter, rare earth industry. Besides, it is checked on various parameters.

Standard grade rolled molybdenum plate is use to fabricate molybdenum carrier or Molybdenum Boat. Featured with exceptional strength and high temperature resistance capacity, the welded structure of this metal boat ensures its long working life under extreme stress and high or low temperature prone working environment. Standard grade materials like TZM molybdenum alloy or pure molybdenum and steps like bending, folding, pressing and riveting are adopted for its production. Customers can access this item and also in tailor made configurations. We are counted as an eminent manufacturer of superior grade Molybdenum Boat.